Intelligent Automated Visual Inspections for Industrial Applications - Easy to access, efficient to use

Save money, increase safety, lower windshield time, improve HSE and cut down on emissions

Osperity is the most advanced online intelligent visual monitoring platform for remote asset inspection of distributed oil & gas, utilities and construction sites and assets.

Osperity’s Automated Visual Inspection is a low-cost, high ROI benefit our platform provides. It is proven to reduce time to inspect sites and assets by up to 90% while minimizing risk, reducing carbon footprint and windshield time.

Osperity enables you to manage and access all your sites remotely through a single application, whether using a smartphone, tablet or desktop computer. Using Osperity, organizations can efficiently and conveniently access live and historical images and video of their assets, such as tanks, batteries, hazardous zones, wells, transformers and other critical infrastructure.

During in-person inspections, operators look for many things, including irregularities in the appearance and integrity of their assets, items hazardous to personnel, evidence of leaks, equipment settings, and general site cleanliness.

Depending on the drive time required and the distance inspectors walk, a single inspection can easily take 2-3 hours. This means a daily inspection of a single facility could require upwards of 20 hours a week.

Using Osperity’s Automated Inspections, an online inspection will lower your time inspecting to just one hour a week, a proven reduction up to 90%.

Contact us today and inquire how we can help

Phone: 587-430-0246

Osperity’s Automated Visual Inspections for Industrial Operations is greatly simplifying the inspection process for HSE, producer and production teams.

or call us on 587-430-0246

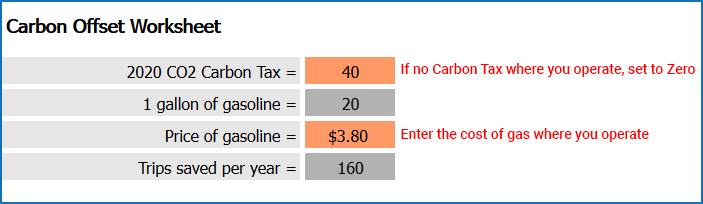

Carbon Emission Offset Calculation Sheet with Savings and ROI

Use this calculator to get an estimate of how much gasoline and CO2 you can save. Pick the one that is applicable to you below (USA / Canada).

The data in this calculator is based on the average savings of clients using Osperity’s Automated Visual Inspections. For more accurate data regarding your situation, please use the form above to contact us.

Applications

Leak Monitoring

Scheduled automated inspections of tanks, well heads, containment areas and equipment to monitor and mitigate leaks

Remote Inspections

Reduce or eliminate the need to have personnel travel to remote distributed assets to do scheduled inspections, while increasing your visibility to the asset and activity surrounding it.

Auditable

With all inspections time and date stamped by a third-party automated system makes the inspections fully auditable by regulators.

Industrial Remote Monitoring

Save Money, Increase Safety, Lower Windshield Time, Improve HSE And Cut Down On Emissions

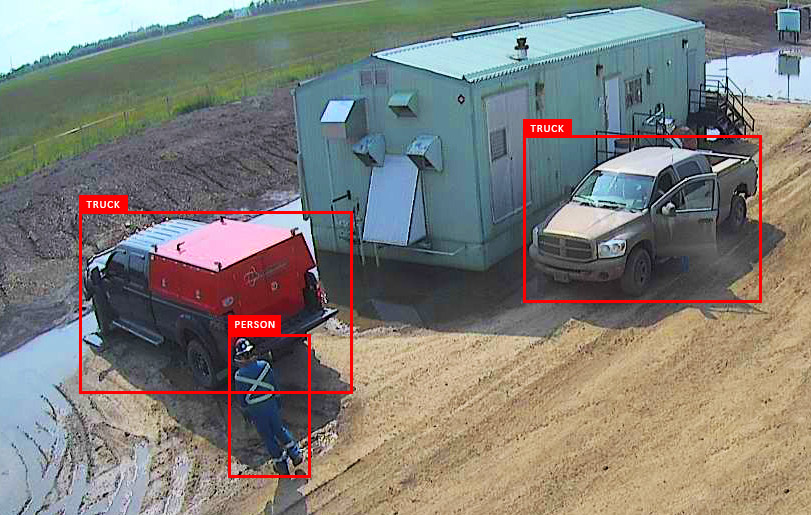

Many sites already have cameras present. Osperity fully support existing remote video industrial camera. These visual sensors can be connected to our platform enabling them to perform image recognition and AI classification.

The Osperity platform is not simply a CCTV surveillance or video surveillance systems (VSaaS) tool streaming to the cloud. We use advanced AI and machine learning tools to train an algorithm to distinguish different things in an image and automatically report on anomalies.

Easily turn images into information to provide real-time detection of events, things of importance and anomalies on the site. This information can be used to better assess productivity, security, risks and hazards.

AI Based Visual Inspections - Benefits

Osperity’s platform captures video from a large number of cameras across a company’s operations. It then analyzes this data with artificial intelligence which automatically detects activity or equipment anomalies from images and video. It also correlates data from other sensors and systems, for greater context and reliability. End users can then be notified on events of interest by creating personalized alerts and reports.

EHS / HSE

Osperity Inspections makes it possible to automate inspections remotely, creating better oversight and decreased response times to events, while reducing risk of injury and greenhouse gas emissions.

Financial

Monitor that personnel is wearing proper PPE. Time traveling to and from the field.

Greatly reduce time conducting inspections.

Vehicle fuel, wear, tear and insurance.

Faster response times to events.

Auditability

All inspections are available online and can be downloaded for offline viewing and storage.

Reports are available to comply with internal and regulatory policies and to help with incidental investigations.

Functionality / Workflow

With Osperity’s Automated Visual Inspections for Industrial Operations, you gain instant access (either online or via a PDF document sent through email) to a single location that includes images taken from selected cameras at the same scheduled time of day.

Inspection Form

Administrators start by creating an inspection form. The form enables them to select the cameras, image order, people and schedule for the recurring inspection.

Inspection Report

An inspection report is the output from an inspection form. The report is available as a PDF, accessed online or through an auto-generated

email, and in the web application.

Camera Selection

Order of Images

Roles

For security purposes and workflow management, users can be given different roles to limit who can create (Administrator) and edit (Editor) inspections forms, and view (Viewer) reports.

Schedule

Administrators and Editors can add one or more schedules to each inspection form. A schedule consists of a time and date the report will be generated and delivered.

User Permissions

Administrators and Editors can add one or more users to receive scheduled inspection reports, and change the distribution list anytime.

Self-Management

Client Administrators can manage the inspection workflow on their own, scheduling as many inspections as they want and pausing them

when necessary.